Pipes that carry water or gas cannot always go straight. They need to turn corners and go around things. An elbow pipe fitting makes this possible.

An elbow fitting is a special connector for turns. It is also called an elbow joint pipe. Workers put it between two pipes to create a specific angle. Without it, building complex pipe systems for homes or factories would be very difficult.

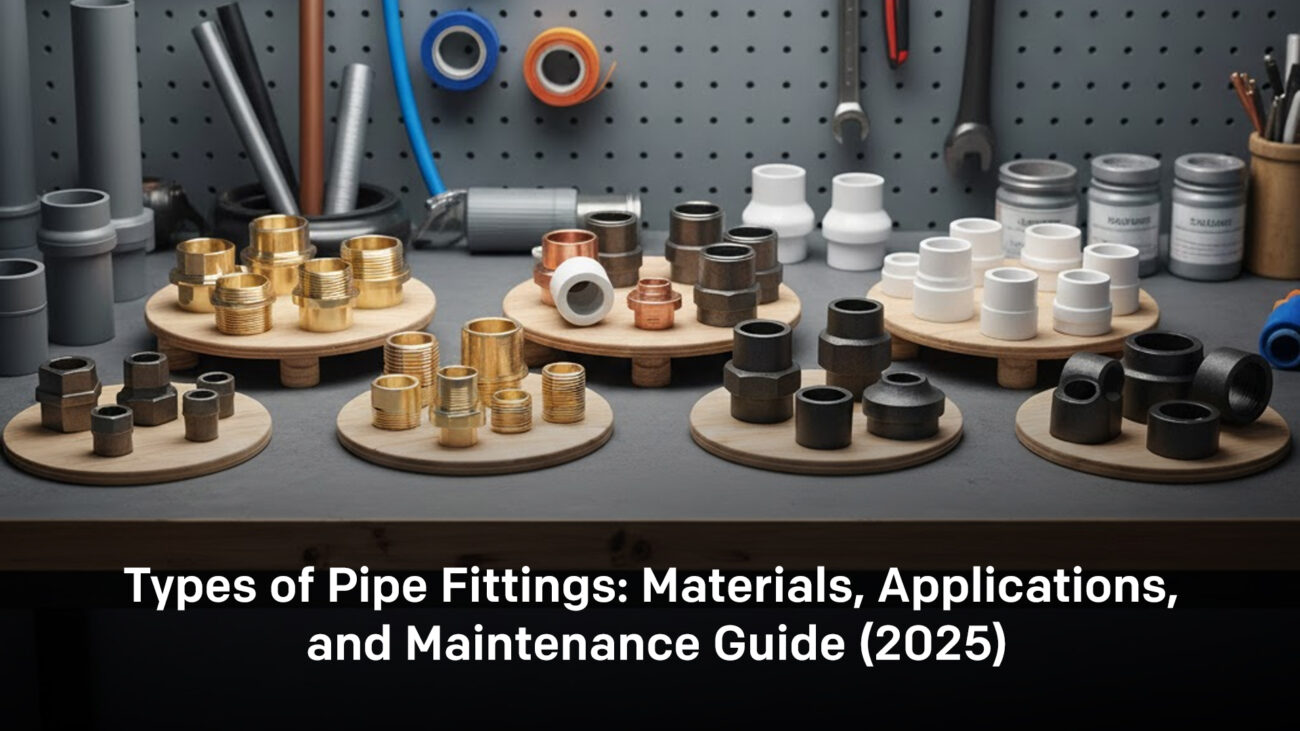

These fittings come in many materials. HDPE pipe fittings are a common choice. They are flexible and do not rust. Picking the right type is very important. You should always work with trusted pipe fittings manufacturers. They make sure the parts are safe and will last a long time.

What is an Elbow Pipe Fitting?

A connector that enables a piping system to change direction is called an elbow pipe fitting. Straight pipes are unable to navigate around obstacles or corners, which is a common requirement for pipes. By establishing a set angle between two linked pipes, the elbow fitting resolves this issue.

This component is fundamental in constructing any network that carries fluids or gases. You will find elbow joint pipe components in water lines inside your home, in large industrial factories, and in agricultural irrigation systems. Their primary job is to direct the flow precisely where it needs to go.

Common Types of Elbow Fittings

Not all turns in a piping system are the same. Some require a sharp corner, while others need a gradual curve. To meet these different needs, pipe fitting manufacturers produce several standard types of elbow pipe fitting designs. The right choice depends on the required direction change and the available space.

Elbows are primarily categorized by their angle. The angle tells you how much the direction of the flow will change.

- 90-Degree Elbow: This is the most common elbow fitting. It creates a sharp, L-shaped corner. It helps in turning the flow a quarter of the way around a circle. You see these wherever a pipe must make a perfect right-angle turn.

- 45-Degree Elbow: This fitting provides a gentler, diagonal turn. It changes the direction by one-eighth of a circle and is often used to navigate slight obstacles or to connect pipes that are not aligned.

- 180-Degree Elbow: Also called a return bend, this elbow joint pipe makes a complete U-turn. It is used to double the flow back in the direction it came from. It is common in heat exchangers and boiler systems.

Beyond the angle, the tightness of the bend is also crucial. This is known as the radius.

A Long Radius (LR) elbow has a gentle, sweeping curve. Its radius is 1.5 times the diameter of the pipe. This design reduces friction and pressure loss. It is ideal for systems where smooth flow is important. A Short Radius (SR) elbow has a much tighter bend. Its radius is equal to the pipe’s diameter. It is used in tight spaces where there is no room for a longer curve.

Some specialized designs combine functions. A reducing elbow, for instance, changes the direction of the flow while also connecting two pipes of different sizes. This saves the need for a separate reducer fitting.

Materials Used in Elbow Fittings

The material of your elbow pipe fitting is a very important choice. It decides what can flow through it. It also affects the fitting’s lifespan and where you can use it. Good pipe fitting manufacturers make these parts from different stuff for different jobs.

- Stainless Steel: This metal is strong and fights rust. Use a stainless steel elbow joint pipe for chemicals, food, or water. It works well with high heat and high pressure.

- PVC: This plastic is light and will not rust. PVC elbow fitting parts are common in home drains and cold water pipes. They are affordable and simple to use.

- HDPE: HDPE pipe fittings are tough and can bend. They are perfect for buried pipes like city water lines. They handle shifting ground and resist chemicals. Their fused joints also help stop leaks.

- Brass: This metal resists corrosion well. You often see small brass fittings in home water lines. It is also used for decorative looks.

- Carbon Steel: This material is chosen for its great strength. Carbon steel elbows go in tough places like power plants. They handle very high pressure and heat.

Choosing Elbow Pipe Fitting

Picking the right elbow pipe fitting is a step-by-step task. A bad choice can cause leaks or breaks. Use this guide to find the best part for your system.

- Check the Fluid: Know what will flow through the pipe. Water, chemicals, and gas need different materials. Corrosive liquids need stainless steel. Simple water lines can use PVC or HDPE pipe fittings.

- Match Pipe Material and Size: The elbow joint pipe must fit your current pipes. Check the pipe material and its Nominal Pipe Size (NPS). You cannot connect a steel elbow fitting to a plastic pipe directly. Sizes must also match exactly.

- Pick the Angle and Radius: Decide how sharp the turn should be. A 90-degree elbow makes a square corner. A 45-degree elbow makes a slanted turn. Use a long radius for better flow. A short radius works in tight spaces.

- Choose a Connection Type: Decide how the fitting attaches. Threaded ends screw on. Socket-weld and butt-weld ends are permanent. Flanged connections can be unbolted later. Your choice changes the cost and installation time.

- Confirm Pressure and Temperature: Every fitting has limits. Check the system’s pressure and heat levels. Make sure they do not exceed the ratings from the Pipe Fittings Manufacturers. This keeps the system safe and working properly.

Common Applications of Elbow Fittings

An elbow pipe fitting is used in many different places. The job determines which type you need. Pipe fittings manufacturers make many kinds for these uses.

- Plumbing Systems: Pipes inside buildings need to turn corners. An elbow joint pipe directs water to faucets and drains waste away. It helps pipes run through walls and floors.

- Irrigation and Agriculture: Water must be guided around farms and gardens. HDPE pipe fittings are common here. They resist rust and last a long time underground.

- Industrial Processing: Factories and plants use strong elbow fitting parts. They move chemicals, oil, and food. These systems often need special materials like stainless steel.

- HVAC Systems: Heating and cooling systems need pipes too. Elbows help route pipes for water or refrigerant. They connect large units like boilers and air handlers throughout a building.

Installation Tips and Maintenance Advice

A good installation keeps your piping system working for a long time. A correctly installed elbow pipe fitting stops leaks. It also helps maintain the correct pressure in the pipes. Following the right steps from the beginning saves you time. It also saves money on future fixes.

Installation Best Practices

Before connecting any pipes, a few preparatory steps are crucial. These steps help avoid common installation errors.

- Inspect the Fitting: Check the new elbow fitting before you use it. Look for cracks, dirt, or any damage. Even good pipe fittings manufacturers can sometimes have a flawed product.

- Prepare the Pipe Ends: Make sure the pipe ends are cut straight. Remove any rough edges. For threaded pipes, check that the threads are not damaged. For HDPE pipe fittings, the pipe end must be smooth and cut square.

- Use the Right Method: Follow the correct procedure for your connection type. Use thread seal tape on threaded joints. Apply the correct primer and cement for solvent-weld PVC. For butt-welding HDPE pipe fittings, use the proper fusion equipment and technique.

- Align Before Final Connection: Misalignment puts stress on the elbow joint pipe. Always ensure the pipes are properly aligned before tightening threads or completing a weld. A forced fit will likely lead to a failure.

Ongoing Maintenance and Inspection

Check your pipes and fittings regularly. A good installation still needs watching. Small problems can be fixed before they get big.

Look at all the pipes and fittings you can see. Check around each elbow pipe fitting for wet spots, rust, or white crusty deposits. In factories, listen for new or unusual sounds in the pipes. This can mean something is wearing out. For buried pipes made with HDPE pipe fittings, watch for low water pressure. A pressure drop can mean a leak underground.

Replace any elbow fitting that is badly rusted, cracked, or keeps leaking. Always get a new one from trusted pipe fittings manufacturers. This makes sure the part is the same quality as the original. It keeps your system strong and safe.

Arihant Plast is a known company in this field. We are one of the main pipe fittings manufacturers. We focus on making plastic piping parts. Our main products are Hdpe pipe fittings. We make many kinds of these fittings. Our products are strong and can handle chemicals. This makes us good for tough jobs like water systems and factory pipes.

Within this category, you will find the essential elbow pipe fitting. Arihant Plast manufactures these elbow fitting components in standard angles like 90 and 45 degrees. Our elbow joint pipe products are designed to create reliable, leak-free directional changes in HDPE piping systems.

The company serves a wide market, providing these fittings for infrastructure projects, agricultural irrigation, and various industrial uses.

FAQs

1.What does an elbow pipe fitting do?

An elbow pipe fitting changes a pipe’s direction. It helps the pipe go around corners or past objects.

2.When do I need a long radius elbow?

Pick a long radius elbow joint pipe for a wide, smooth curve. It helps liquid flow easily with less friction and pressure loss.

3.Why do people use HDPE pipe fittings?

HDPE pipe fittings are common because they fight chemicals and rust well. They are also bendable and strong. This makes them perfect for buried pipes and factory use.

4.What is ‘Schedule’ for an elbow?

Schedule means how thick the elbow joint pipe wall is. A bigger number, like Schedule 80, means a thicker wall. A thick wall can hold more pressure.

5.How do I take care of my elbow fittings?

Look at them often. Check for leaks, rust, or breaks. In systems with pressure, watch for pressure going down. This can mean an elbow fitting is leaking.