A small drip from a pipe joint can cause a major problem. It can lead to water damage and require expensive repairs. The connection points in any plumbing system are critical. They must be strong and reliable.

For generations, one material has been trusted for these vital connections. Brass fittings are known for their performance and long service life. They form a secure link between pipes. It ensures that water flows only where it is supposed to.

Why Brass? The Unbeatable Advantages for Modern Plumbing

Plumbing systems rely on connections that will not fail. Among the options available, brass pipe fittings have remained a consistent choice. This is due to a combination of properties that other materials struggle to match.

The performance of brass plumbing fittings comes from the material itself. Brass is strong. It can handle high water pressure without cracking. It also resists rust and corrosion far better than many other metals. This is crucial for long-term use with water.

These fittings perform well in different temperatures. They are suitable for both hot and cold water lines. This versatility simplifies supply planning.

Brass is a practical material to work with. It is softer than steel. This makes it easier to cut and thread. This helps create a tight, secure connection that will not leak. When installed correctly, that seal can last for many years.

Brass Ferrules is also very durable. A plumbing system with good-quality brass fittings can work properly for decades. This means you avoid the cost and trouble of frequent fixes or replacements. It is a single purchase that provides value for a long time.

Finally, brass is good for the environment. Old brass fittings are not thrown away. They can be recycled by melting them to make new products. This makes brass a smart and responsible choice.

Brass Fittings vs. Other Materials

The following comparison is based on practical application to help inform your choice.

Brass Fittings vs. Plastic Fittings

Brass plumbing fittings work better in situations that demand higher performance.

- Heat Resistance: Plastic is soft. It can melt if it gets too hot. Brass stays strong, even with very hot water. So it is safe to use for water heaters.

- Strength: Plastic can crack if it is hit or bent. Brass is much stronger. It does not crack easily. It can also handle strong water pressure for a very long time.

- Thread Integrity: Threads made from brass are stronger. They are less prone to stripping during installation or maintenance compared to plastic threads.

Many pipe fitting manufacturers produce both types because they serve different needs. Plastic may be chosen for budget-specific cold water lines. Brass is selected for its all-round performance and longevity.

Read More Also – Top 10 HDPE Pipe Fittings Manufacturers in India

Brass Fittings vs. HDPE Pipe Fittings

HDPE pipe fittings are specialists for specific, large-scale projects. They excel in extensive underground applications such as municipal water mains, agricultural irrigation, and industrial effluent lines. Their key advantages in these settings are exceptional flexibility and high corrosion resistance.

Brass fittings, on the other hand, are used for internal plumbing systems.

- Application Scope: HDPE systems are fused together, creating a permanent joint. Brass systems use mechanical joints, which allow for disassembly and repair.

- Function: You would not use HDPE pipe fittings to connect a shower valve or a kitchen faucet. These internal, high-point-load connections are the domain of brass.

Leading brass fittings manufacturers in India position brass for building interiors and HDPE for exterior and civil applications.

Brass Fittings vs. Stainless Steel

The choice between them often comes down to two factors.

- Cost: Brass typically offers a more cost-effective solution for standard plumbing needs.

- Workability: Brass is easier to machine and thread. This can lead to faster installation and a lower risk of assembly issues.

Stainless steel may be specified in environments with highly corrosive chemicals, but for standard potable water, brass provides an optimal balance of performance and value.

This comparison within our brass fittings: the ultimate guide shows that no single material is best for every situation. The decision depends on the specific requirements of the project, a point that informed pipe fittings manufacturers understand well.

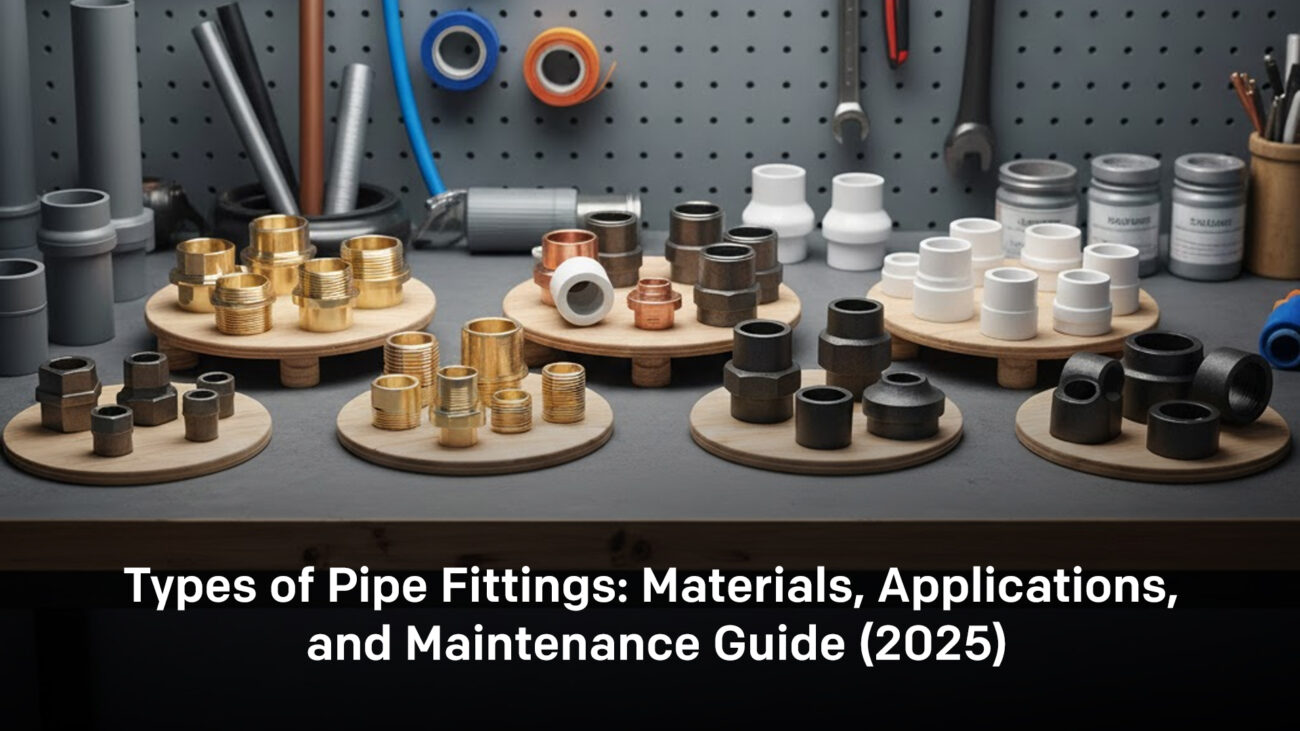

A Comprehensive Guide to Brass Fitting Types

A plumbing system needs connections. This is where brass pipe fittings come in. They are the components that direct and control the flow. Brass fittings are systematically categorized by their connection method and function.

Grouped by Connection Method

The way a fitting joins to a pipe determines its use and installation process.

- Compression Fittings: These are common under sinks and toilets. A nut and a ferrule ring tighten around the pipe. This creates a seal without heat or threads. They allow for easy disassembly.

- Threaded Fittings: These have screw threads on the inside or outside. They twist onto threaded pipes. Sealant tape is often used to ensure a tight, leak-proof connection. They are a standard in many plumbing systems.

- Push-to-Connect Fittings: These provide a very fast installation. You simply push the pipe into the fitting until it clicks. An internal O-ring creates the seal. They are useful for quick repairs or in tight spaces.

Reliable brass fittings manufacturers in India produce all these types to meet different installation needs.

Grouped by Shape and Function

Each fitting shape has a specific purpose in directing flow.

- Elbow: This fitting changes the direction of a pipe. It is commonly available in 90-degree and 45-degree angles.

- Tee: This shape allows one pipe line to be split into two. It creates a T-shaped intersection in the plumbing system.

- Coupling: A coupling joins two straight pipes of the same diameter together in a line.

Union: Similar to a coupling, but it can be unscrewed. This makes it useful for sections of pipe that may need future maintenance. - Adapter: These are used to connect pipes of different types or sizes. For example, an adapter might connect a brass pipe to a different material.

The Arihant Plast Standard: Quality You Can Trust

At Arihant Plast, our reputation is built on a foundational principle: unwavering consistency.

This commitment begins at the source. We select specific grades of brass that are certified for plumbing applications. This guarantees that our brass plumbing fittings offer superior corrosion resistance. We make sure that they are engineered to withstand daily operational demands. This ensures a long-lasting performance.

Precision in manufacturing is critical. Our production techniques ensure every thread is sharp and every surface is smooth. This attention to detail means our fittings create a perfect seal. It prevents leaks and simplifies installation for plumbers.

We operate with a system of checks. Our quality control team examines fittings at different stages of production. This process identifies any issues before a product is packaged. For us, consistent quality is more important than speed.

As one of the prominent brass fittings manufacturers in India, we recognize our responsibility. Our role is to supply components that professionals can install with confidence. These components become a permanent part of a building’s infrastructure.

Our work as pipe fittings manufacturers also includes HDPE pipe fittings. This gives us a broad view of plumbing systems. HDPE pipe fittings and brass fittings have distinct but equally significant uses. This information enables us to help our clients choose the best course of action for each unique project.

This commitment defines the Arihant Plast standard. It is the foundation we provide in these brass fittings: the ultimate guide. We consistently produce goods that meet or exceed expectations. Because they can be certain in the quality of the components they are employing, engineers, plumbers, and builders can concentrate on their task.

As one of the brass fittings manufacturers in India, Arihant Plast is committed to this standard of quality. We manufacture components that professionals can trust. Our work as pipe fittings manufacturers also gives us insight into the specific roles of different materials, such as HDPE pipe fittings for underground civil projects.