Pipe systems rarely get attention unless something goes wrong. A small leak, a sudden pressure drop, or a damaged joint can disrupt operations and lead to expensive repairs. In most cases, these issues are not caused by poor materials but by avoidable installation errors. Since pipe fittings play a critical role in connecting and controlling flow, even minor mistakes can compromise the entire system.

This blog highlights the most common pipe fitting installation mistakes and explains how to avoid them using practical, up to date best practices. Whether you’re working on plumbing, irrigation, or industrial pipelines, these insights can help you achieve long lasting and reliable results.

Image Source – Freepik

Why Correct Pipe Fittings Installation Is Essential

Pipe fittings are responsible for:

- Joining pipe sections

- Changing flow direction

- Adapting different pipe sizes

- Managing pressure and movement

Improper installation can lead to leaks, premature wear, and system failure. This is especially true for modern systems using HDPE pipe fittings, where correct handling and joint preparation are essential to performance and lifespan.

Common Pipe Fittings Installation Mistakes

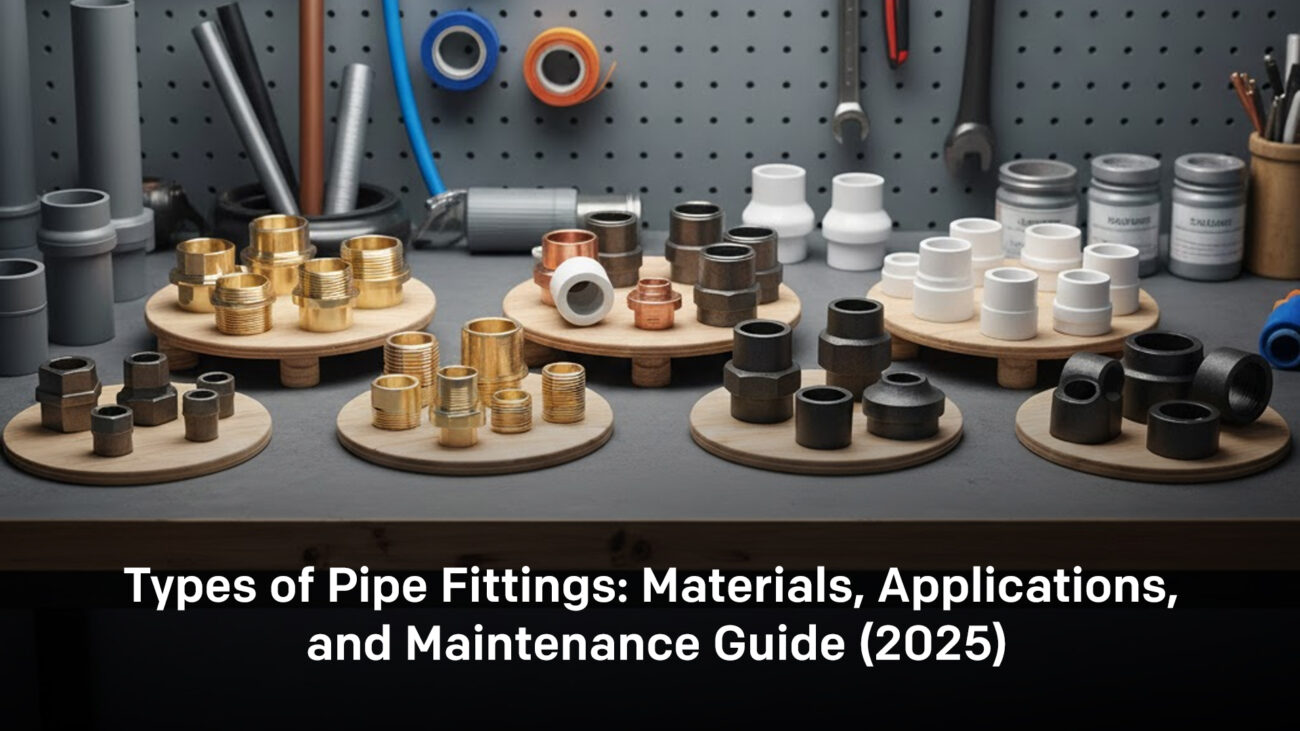

Choosing the Wrong Pipe Fittings Material

Selecting fittings without considering the application is one of the most common mistakes.

Image Source – Freepik

Typical problems include:

- Using fittings not rated for the required pressure or temperature

- Choosing materials incompatible with the fluid being transported

- Mixing materials that lead to corrosion or joint failure

How to avoid it:

Always match pipe fittings to operating conditions, including pressure, temperature, and chemical exposure. Consulting technical specifications and working with an experienced pipe fittings supplier helps prevent costly material mismatches.

Poor Surface and Joint Preparation

Even high quality fittings fail when joints are poorly prepared.

Common issues:

- Dirt, grease, or moisture on pipe ends

- Burrs left after cutting

- Uneven surfaces affect sealing

How to avoid it:

Clean, deburr, and dry all pipe ends before joining. For HDPE pipe fittings, proper surface preparation is critical for secure fusion or mechanical joints.

Incorrect Alignment and Forced Connections

Forcing pipes into position creates hidden stress that weakens joints over time.

Risks include:

- Cracks in fittings

- Constant pressure on joints

- Reduced system life

How to avoid it:

Ensure pipes and fittings align naturally. Use supports and guides to maintain proper positioning, especially in long pipe runs.

Over Tightening or Under Tightening Fittings

Incorrect tightening is a frequent and often overlooked issue.

What goes wrong:

- Over tightening can crack fittings

- Under tightening leads to leaks

How to avoid it:

Follow manufacturer torque guidelines and use appropriate tools. Tightening should be firm, controlled, and consistent.

Ignoring Thermal Expansion and Movement

Pipes expand and contract with changes in temperature.

Common consequences:

- Joint separation

- Warped pipelines

- Stress fractures

How to avoid it:

Incorporate expansion loops, flexible joints, or compensators into system design, particularly in outdoor or industrial installations.

Skipping Pressure Testing

Skipping pressure testing often leads to undetected problems.

Image Source – Freepik

Why it’s risky:

- Hidden leaks appear during operation

- Weak joints fail under load

How to avoid it:

Always conduct pressure testing before commissioning the system. Testing confirms joint integrity and overall system safety.

Best Practices to Avoid Pipe Fitting Installation Errors

Follow Manufacturer Instructions

Each type of pipe fitting has specific installation requirements. Ignoring them increases the risk of failure and may void warranties.

Work With a Reliable Pipe Fittings Supplier

A dependable HDPE pipe fittings supplier provides:

- Certified, quality-tested products

- Clear technical documentation

- Guidance on correct installation methods

The right supplier becomes a valuable partner, not just a vendor.

Use Proper Tools and Skilled Installers

Using the correct tools and trained installers significantly reduces errors. Investing in proper equipment and training improves consistency and safety.

Inspect, Test, and Document the System

Routine inspections and proper documentation help identify issues early and simplify future maintenance.

Conclusion

Most pipe system failures trace back to small, preventable installation mistakes. By choosing the right materials, preparing joints carefully, following installation guidelines, and testing thoroughly, you can ensure your pipe fittings perform reliably for years. Whether you’re installing standard pipelines or advanced HDPE systems, attention to detail and working with a trusted pipe fittings supplier make all the difference. Looking to learn more or explore quality pipe fittings solutions? Browse our related resources or connect with an expert today.